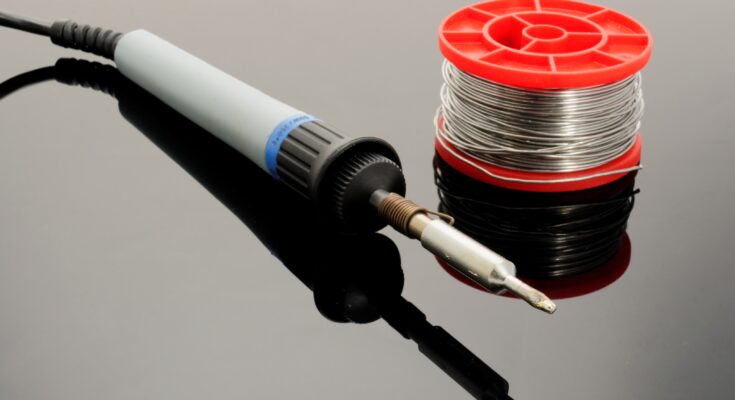

A soldering iron is a device used to solder electronic circuits to each other. The soldering process occurs when the soldering iron produces high heat and melts the solder wires. The soldering iron tip is generally divided into two classes, copper or nickel.

This is because copper and nickel materials are resistant to intense heat and electricity. The intense heat required for the soldering process is supplied by the power capacity of the soldering iron. Soldering irons generally consist of 40 Watts and 220 Volts. The ideal power capacity is in this direction. Soldering may be needed in many places.

The main area in which the soldering iron plays a role is in the soldering of electronic circuits and similar circuits. The use of soldering irons has become an important advantage for those who deal with electronic circuits today, due to the time savings it provides, as well as increasing the quality of the work to be done.

Soldering Iron Types

Soldering irons are divided into types according to their usage areas.

Commonly used soldering iron types are:

- Standard Pen Soldering Iron.

- Multi-Purpose Soldering Iron.

Apart from these commonly preferred soldering iron models, soldering irons can also vary according to their power capacities. These are the soldering iron types used as 40Watt 220 Volt, 60Watt 220 Volt, 30Watt 220 Volt. Soldering irons between 30 Watt and 60 Watt are the ideal types of soldering irons, according to their prevalence.

What are the Standard Pen Soldering Iron Features?

Soldering irons should reach high temperatures quickly due to the area they are used in. At the same time, it is important that there is no heat loss during soldering. Standard soldering irons have these features, as well as being heat-insulated in terms of body, which is an important issue in terms of work safety.

What are the Features of Multi-Purpose Soldering Iron?

The most important feature of multi-purpose soldering irons, which have various soldering stages compared to standard soldering irons, is that they can operate on mains electricity.

What are the Usage Areas of Soldering Iron According to Watt and Volt Degrees?

The power capacity of soldering irons is directly proportional to the heat they generate. This causes the use of soldering irons with different Watt options in the works to be done. 30Watt soldering irons are used when soldering resistor, capacitor, diode and transistor elements. 40Watt soldering irons are used in circuits with high power capacity and small circuits.

Soldering irons of 60 Watt and above are used when soldering much larger circuits. 30 Watt and 60Watt soldering irons are the most preferred soldering iron types. It is often preferred due to its power capacities being suitable for most jobs and ease of use. At the same time, it is extremely important in terms of safety that the Watt degrees are suitable for the work to be done in terms of occupational safety.

What Should Be Considered When Choosing a Soldering Iron?

The selection of the appropriate soldering iron should parallel the work to be done. Releasing more heat than needed during soldering can damage electronic circuits. In this sense, the Watt and Volt degrees of the soldering iron needed should be known before choosing the soldering iron. Another thing to consider when choosing a soldering iron is ease of use.

It is absolutely necessary to learn how to use the selected soldering iron. Otherwise, there are risks that may arise during the work. The soldering process takes place thanks to the instantaneous intense heat generated by the soldering iron. Therefore, soldering irons that do not provide convenience in terms of use may contain security risks.

Also Read: Top 5 Benefits of Video Editing Tool for Small Business Marketing

How to Solder Correctly?

The soldering process is done using soldering iron devices.

The steps to be followed in order to make a good solder are as follows;

- The area to be soldered should be cleaned.

- Correct Soldering Iron Selection should be made according to the job to be done.

- The Soldering Iron Tip must be cleaned.

- The temperature of the soldering iron should be adjusted according to the need.

- Solder should be used as needed.

- Soldered parts should not be played for a while after soldering.

The soldering process is extremely important. Incorrect soldering can cause the soldered circuits to fail. In order to prevent this, extreme care must be taken. The most important factor to be considered for a correct soldering is the use of the correct soldering iron. A soldering iron chosen for the job constitutes half of a good soldering process.

What Are the Safety Precautions That Can Be Taken While Soldering?

The intense heat generated by soldering iron devices is a matter to be considered. At the same time, the toxic gases generated during the soldering process and the amount of lead remaining depending on the soldered material can be harmful.

Therefore, hands must be washed after soldering. Otherwise, lead residues, which are likely to be contaminated, may pass into the body through the skin. One of the important issues is that the soldering room must be an airy place. Otherwise, the toxic gases produced during soldering may cause serious damage.

After the soldering process is finished, the tip of the soldering iron should never be touched. The tip, which has intense heat, can cause serious burns. Finally, the contact of the soldering iron with the cable should be avoided. If not avoided, the cable may melt and cause a short circuit.